|

Contract Manufacturing and Assembly

|

|

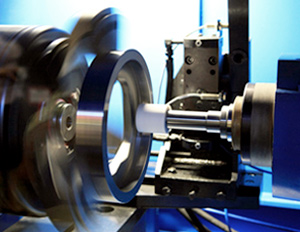

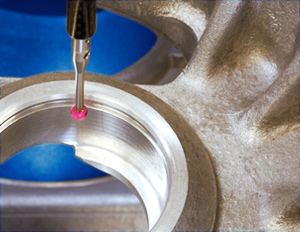

As service provider we offer contract manufacturing for all metals and plastics as well as assembly and functional testing of assemblies and systems. Contract Manufacturing of components made of metals and synthetic materials:

Surface Treatment:

3D-Prototyping:

Assembly of assemblies and devices:

All services and quality assurance from a single source, for prototypes and series production. |

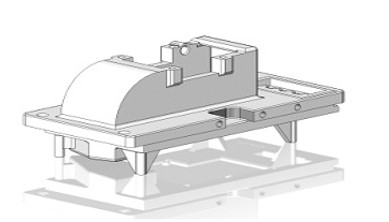

Quickly available tools and equipment for productionTools and equipment can increase productivity and manufacturing quality. With small measures, large savings in costs can be achieved. GWK Precision Technology is a specialist in the fast and precisely fitting engineering of tools, equipment, devices and measuring equipment. When inspecting production sites, we see potential for optimization with a trained eye:

This is followed up by an action plan proposal:

A needs-based improvement of the production environment may include the analysis of production processes, measures for optimization as well as the engineering and manufacturing of equipment. |

Copyright © 2024 GWK Präzisionstechnik GmbH. All rights reserved. Impressum Datenschutz |